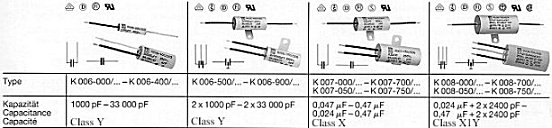

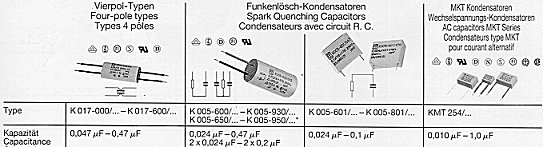

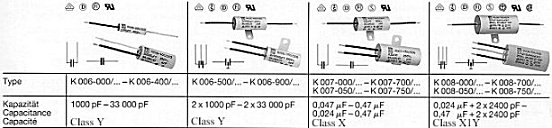

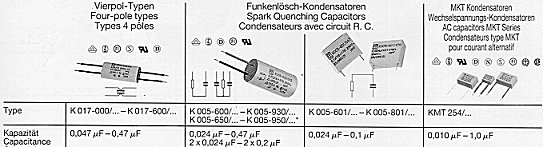

Line filters are made in a wide variety of types and sizes, small PCB mount, larger panel mount, power entry filters to protect a room or a building, low leakage medical grades, 3-phase, with switchs and fuses. Some pictures of line-filter capacitors and snubbers:

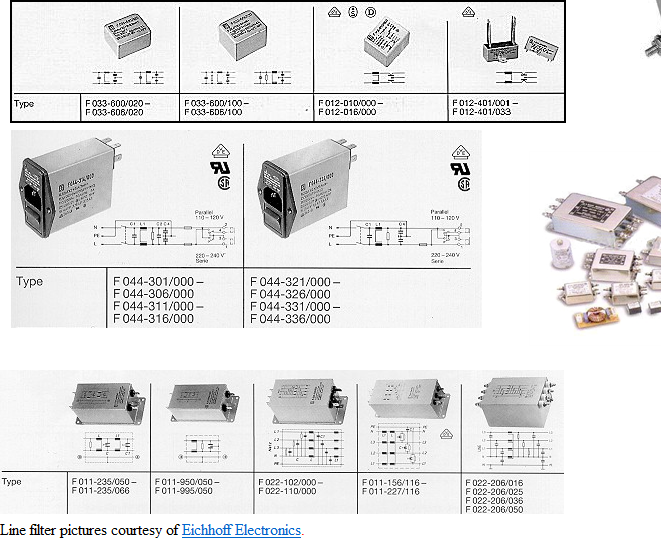

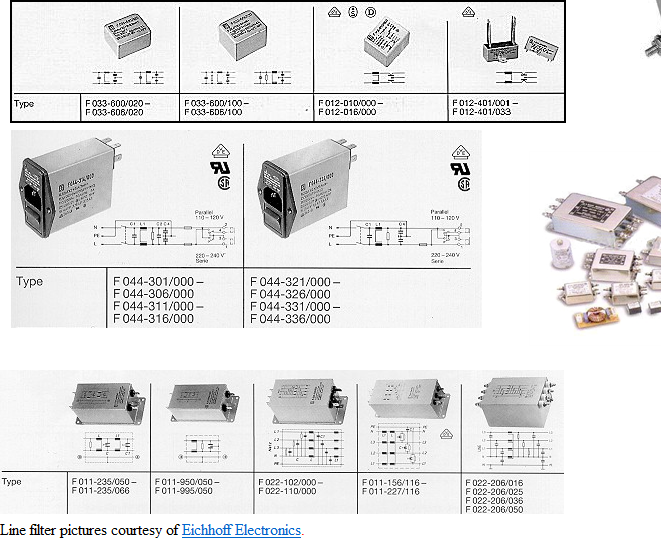

Some examples of complete filter modules:

Companies that make line filters include:

Thanks to John Woodgate who wrote much of this page.

A special class of capacitor is used in power-line (mains) filters. Line filtering is a very tough application for a capacitor. Power lines are subject to a variety of disturbances that induce transients and surges. These vary from a few hundred or a few thousand volts (motors and triac controllers) to many thousands of volts (lightning). The filter capacitor has to endure these transients for years without failure, or at worst, failing without exploding, catching fire, or subjecting the user to the risk of shock.

Line-filter capacitors are used for a number of purposes. The first is to keep potentially disruptive or damaging line transients and EMI out of susceptible equipment.

The second is to suppress these line disturbances at the source. Typical offending equipment includes motors and motor controls, relays, switching power supplies (more and more common), inverters, and solid-state load controls using triacs, SCRs, and IGBTs.

The third use of line-filter capacitors is in a sort of snubber called a "spark quencher". A spark quencher is a potted series R-C network, where the capacitor is typically from 0.01 to 2 uF, and the resistor is from 10 to 500 ohms. The resistor lowers the "Q" to suppress L-C ringing. People who make the capacitors will usually make the spark quenchers as well. Spark quenchers are used to protect switches, relays, triacs, and scrs from transients generated from switching inductive loads, and to suppress RF generated by contact arcing. Ideally, both the R and the C should be correctly sized for each application; as the load current goes up, the capacitor size goes up and the resistor value falls. The resistor type is not always stated, but some people use carbon composite resistors for their good peak current handling capability. Not every manufacturer makes a broad selection of R-C combinations however. Spark quenchers are aimed at relatively low current and low voltage applications, no more than 10 A and 250 Volts AC or DC.

For more information on spark quenchers and contact protection, try these sites:

Some consumer electronics uses the mains as a cheap (if dirty) antenna. A small but very reliable capacitor must be used to pass RF, but block line frequency and protect the user. They are also used to isolate the antenna from high-voltage DC in the transmitter.

Epoxy-filled metallized paper, metallized polyester film, polypropylene, and ceramic (typically Z5U but other materials are available, even C0G) are the common dielectrics for line-filter capacitors although film-foil polyester, and paper-polyester, have also been used at one time or another. The film dielectrics are used both with and without oil inpregnation. The metallization can be aluminum, but zinc and other metals may be used for better self-healing. Why the variety of materials? Some manufacturers (see Rifa) argue that epoxy-paper is safer and more reliable because of its better self-healing properties and voidless construction (which helps prevent corona). Also, epoxy-paper can´t be made to burn. However, the conventional plastic films, with their higher dielectric strengths, result in a smaller part where space is critical. Epoxy-paper capacitors can be 30-100% larger in volume of their plastic-film equivalents, and they are not found in the higher values. This has helped to make polypropylene the more popular dielectric. It also has good self healing. Epoxy-paper's other electrical properties (temperature drift, dissipation factor) are poor so you won't see this dielectric in other applications very often. Epoxy-paper caps are available without approvals, but are not common. WIMA and Rifa/KEMET may be the only companies to make epoxy-paper line-filter capacitors. Polypropylene is probably best used where there is a lot of high-frequency energy to be filtered.

Line-filter capacitors come in two general classes (as defined by the International Electrotechnical Commission (IEC), the international standards organization for electrical and electronics matters) and must be approved by whichever safety agency holds sway where the equipment will be sold. In fact, you can always recognize a line-filter capacitor by the "EN132400" printed on it, plus agency acronyms (UL, VDE, CSA, etc.). Older capacitors would have the symbols for SEMKO, DEMKO, and others, but these no longer exist as governmental agencies and are, if they exist at all, commercial enterprises carrying out testing.

The IEC only produces standards, not legally-binding regulations. Many IEC standards are adopted in Europe by CENELEC as European Standards (ENs), which may effectively be legally binding if they can be used to demonstrate compliance with a Directive, such as the Low Voltage Directive. Most are adopted unchanged, but some ENs have Common Modifications, which apply all over the CENELEC area, and Special National Conditions, which apply only in the country concerned.

Class X is for applications where failure could not lead to electric shock (hot to neutral). Class X1 capacitors are intended to operate safely even in the presence of spikes on the mains supply of up to 4 kV (installation category 3 or overvoltage category 3 according to IEC60664), which are normally industrial supplies, but some standards call up class X1 capacitors if they are connected directly to the mains supply upstream of the equipment fuse, irrespective of the type of mains supply. Class X2 capacitors are intended to operate safely even in the presence of spikes on the mains supply of up to 2.5 kV (installation category 2 or overvoltage category 2 according to IEC60060), which are normally residential, commercial and light industrial supplies. X capacitors can be found from 0.001 uF to at least 10 uF and are only made in film.

Class Y capacitors are for applications where failure could lead to electric shock if the ground connection were lost. This includes hot/neutral to ground, and antenna isolation capacitors. Because Y capacitors shunt current to ground, leakage-current limitations limit their size to a maximum of about 4700 pF in many commercial and industrial applications (but refer to the relevant standard for definite information) and about 470 pF in medical applications. Larger ones are available however. Y caps are available from 1000 pF to 0.1 uF and are made in both film and ceramic.

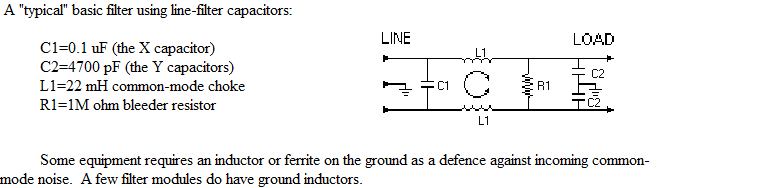

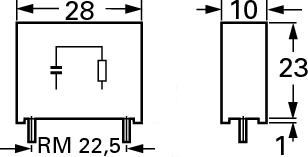

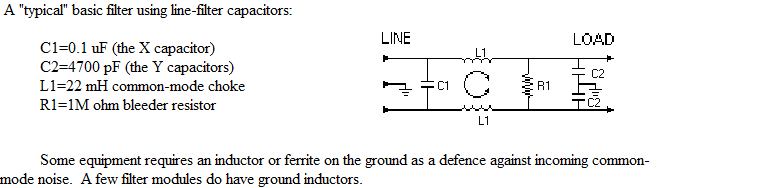

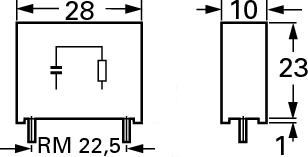

Because most applications require one X and two Y capacitors, multi-capacitor devices are available. Also available are a variety of metal or plastic housing styles, mounting options (pc mount, pigtail) and 4-wire connections. At least one manufacturer (WIMA) has X2 and Y2 capacitors in SMD, with more expected to follow. Line-filter capacitors are most often boxed and potted in epoxy. The box is usually polybutylene terephalate (PBT) for its superior flammability characteristics. This gives better moisture protection than an epoxy dip, or the common "wrap and fill" construction. Line-filter capacitors are also used as components in complete filter modules that include inductors and a bleeder resistor. Multi-capacitor modules can even use mixed dielectrics, such as a 3-phase module where the X capacitors are polyester, and the Ys are polypropylene.

Classes X1, X2, and Y were originally defined by the IEC in IEC 60384-14. CENELEC has adopted EN 132400 (technically equivalent to, but structurally different from IEC 384-14 2nd edition), which now defines seven classes of line-filter capacitors. Class X1 capacitors are impulse tested to 4 kV (higher for capacitors over 1.0 uF). Class X2 capacitors are impulse tested to 2.5 kV (higher for capacitors over 1.0 uF). Class Y1 capacitors are impulse tested to 8 kV, and Class Y2 are impulse tested to 5 kV. Classes X3, Y3, and Y4 are for lower-voltage capacitors, none of which are presently called up in safety standards. X2Y3 ceramics now have some limited availability. Other impulse tests also apply. These include a 1000 hour endurance test during which the capacitor is subjected to a continuous overvoltage condition, plus periodic 1000 VAC spikes, and a flammability test during which the capacitor is hit with a series of transients while under rated voltage. Capacitors conforming to IEC60384-14 normally also conform to EN132400, and vice versa, and should be accepted in all European countries.

Line-filter capacitor voltage ratings are based on what the agency considers the "nominal" line voltage in its jurisdiction to be. A part can have one voltage rating in the US and Canada (125 or 250 VAC), a different rating in Europe (perhaps 275 or 300 VAC), and the manufacturer might recommend its use at a higher voltage yet (a 250 VAC part on a 260 VAC measured line). This can make for a little confusion in application, and it may be best to ask the manufacturer for details.

These capacitors are also rated according to min/max temperature and allowed average annual humidity exposure. IEC 68-1 calls for an X/Y/Z marking system where X is the low-temperature limit, Y is the high-temperature limit, and Z is the number of days tested in a damp heat test (+40C at 93% RH). For example, 40/100/56 would mean the capacitor was rated from -40 to +100C and tested for 56 days in the damp heat test. This is printed on the capacitor.

UL (and CSA) has no blanket policy to cover all line-filter capacitors, it ranges from moderately tough for some equipment to nonexistent for others. The capacitors may be affectively tested when the equipment they are in is tested however. The IEEE has standard IEEE C62.41 (formerly IEEE 587), for industrial equipment where downtime is not an option, even from the effects of lightning strikes. Transients to 8 kV are assumed. This would include uninterruptable power supplies and some computer equipment, all of which would have line-filter capacitors. They differ in spirit from other agency's tests in that while others will pass a capacitor if it fails certain tests safely, the IEEE requires capacitors to survive its very tough tests. However, the capacitors may need the protection of varisters.

See also UL 1414 (some entertainment and communications equipment, similar to CSA C22.2-1), and UL 1283 (potted line-filter modules, similar to CSA C22.2-8).