This is a guide to measuring it.

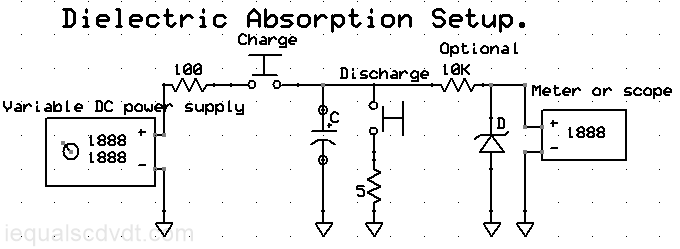

1) The the test capacitor (C) is charged at some voltage for a number of minutes (Tc). The charging time might be one or

more minutes.

2) The Charging Switch is opened, and the Discharge Switch is closed, for perhaps 10 seconds (Td).

3) The Discharge Switch is opened and the voltage on C is monitored with a DVM or oscilloscope for several minutes.

4) The ratio between the original voltage and the final voltage is calculated, in percent. This is the dielectric absorption

number.

5) MIL-C-19978 says charge time = 1 hour, discharge through a 5 ohm resistor for 10 seconds, the final voltage is recorded

after 15 minutes. This is the method many people prefer to use. This is fine except that it might be better to record a curve over

the 15 minutes. A single number will not necessarily tell you all you need to know. Some people will be more interested in what

happens in the first few milliseconds. See standard MIL-C-19978 for the details, it even has a picture.

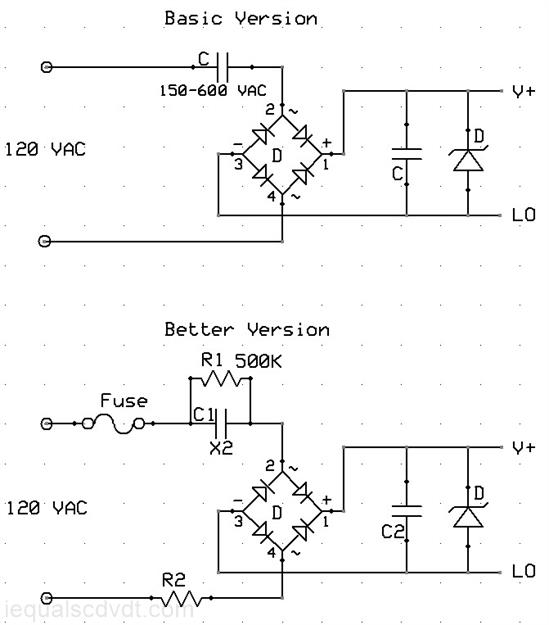

The circuit below has everything you should need for a DA measurement. The 100 ohm resistor limits the charging current to a

level that won't damage the capacitor C or the switch. If the test voltage you use is high enough to damage the meter or (more

likely) the scope, the 10K resister and the zener diode should protect it. The resistors must be made for high-voltage operation,

your basic RN55, 1% parts, won't do. Several RN-70s or something wire-wound maybe.

However, don't expect this test to give you consistent and part-to-part repeatable numbers. What you will get will have some

dependency on the history of the part you are testing. By history I mean applied voltages and temperatures. One possibility

might be to short the capacitor for an extended time and at an elevated temperature to clear out any trapped charge before

testing.

Apparently, at one time one manufacturer offered Teflon capacitors selected for low DA. Why bother with all this? If you are

using low DA caps in a circuit you might actual need to measure the DA. DA varies significantly part to part and batch to batch.

In fact it varies enough to cause some doubt about the exact DA numbers given to various dielectrics. A number of circuit

methods have been devised to compensate for the affects of DA, if only approximately. Many of these have been patented.

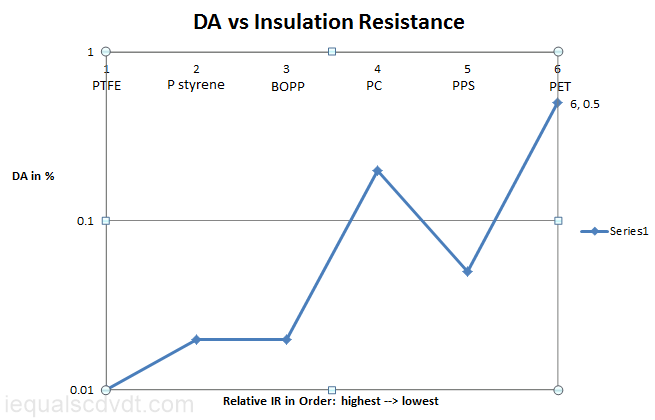

The DA of a dielectric material tends to track with the leakage figure, if not perfectly. This suggests that the DA number you get

might be different for a higher voltage capacitor than lower voltage capacitor, assuming the test voltage is the same. A good

experiment to try, but I don't know that anyone has. There have been reports that the DA of ceramic opamp packages can

cause problems for some analog circuits.

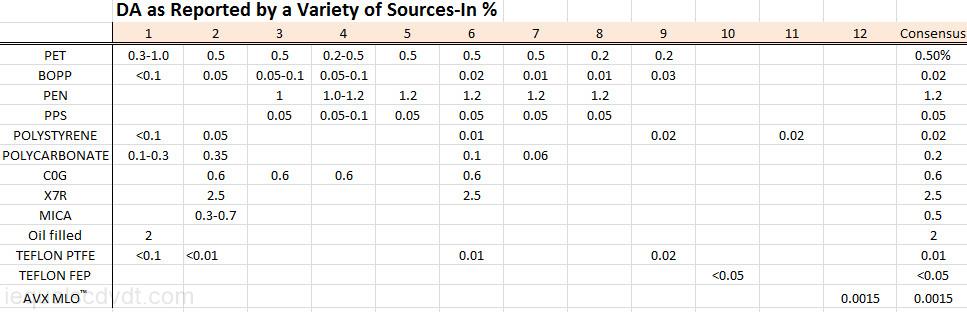

The DA numbers below are for room temperature. DA is very temperature temperature sensitive however. Different dielectrics

behave differently, but The DA might be 20 times higher at 100C than at 25C.

If you found it necessary to build a super low DA capacitor in the 0.001-0.1 uF range, how would you do it? Vacuum makes

the highest resistance dielectric, followed by gasses. These would be very difficult to work with. There are patents on board-

level air-dielectric capacitors, but intended for microwave work, which means very small values. There are some metallic

oxides that have very high resistance, and these might have possibilities. Below are the dielectric absorption numbers from

about a dozen sources. They don't entirely agree with each other.

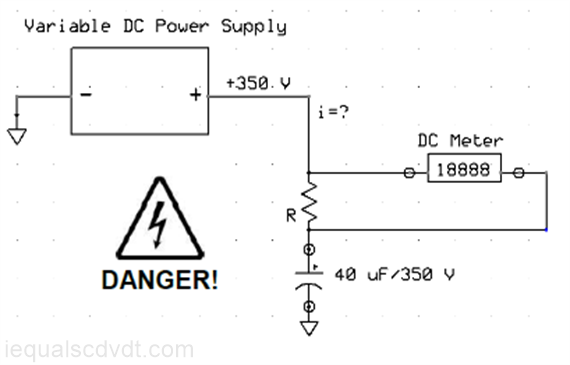

If you are working with voltages >35 volts or so, use appropriate care. If you electrocute yourself, don't blame me. A

capacitor like this can remain charged for a long time after being disconnected. In some cases, if you short it (through a resister),

it can recover enough of its voltage to be lethal, thanks to dielectric absorption.

Audio capacitors:

The "golden-ear" audio crowd says it can hear capacitors. That is, audio equipment will sound different when built with different

kinds (or even brands) of capacitors. These people also think they can hear different brands of solder and line cords, and who

am I to say they can't. Different dielectrics will have an affect on signals in the audio range, but it's not clear at what point the

ear-brain combination can hear those differences. A number of companies make golden-ear audio capacitors that use

dielectrics and electrode foils that may not be found in more common parts. They include bee's wax, Teflon (2 kinds), copper,

silver, tin, oil in paper, and even fluorinert, as well as the usual polystyrene and polypropylene. Several mainstream companies

also sell what they call audio-grade capacitors.

Audio capacitors are used in three places. How would you choose capacitors for each application?

The signal path, low-level equalization, tone controls and DC blocking: The ideal capacitors should not be subject to

voltage modulation, that eliminates the class 2 and 3 ceramics. They should also have minimal dielectric absorption. That

eliminates C0G ceramics, most film capacitors and others. The best would be polystyrene, polypropylene and Teflon.

Power filtering electrolytic capacitors: They should be large, but that's no problem. They should have fairly low ESR

and they should be reliable. I would probably go for low ESR and high-temperature parts for long life. Just for overkill, I

would parallel them with a bunch of polyester films (or maybe X7Rs) for lower ESR. DC link capacitors are showing up in

some designs. They have lower ESR and ESL than ordinary capacitors.

Speaker crossover capacitors (speaker level): There is a general agreement that you should never use electrolytics.

Polypropylene would be better but polyester is probably more common. If it's not practical to avoid electrolytics, polymer-

aluminums might be better that conventional aluminums, assuming you can find the right values and voltages.