Film capacitors are mostly used in high-performance applications. Polycarbonate, polyester, and polypropylene have been the "big three" of film capacitors. They are the only ones that many film capacitor makers make, although polyphenylene sulfide (PPS) may be on the rise. For the lower volume capacitors, I have listed known manufacturers. This does not mean they actually stock parts, but at least they have the capability to make them if they want to.

http://www.epcos-china.com/blob/541236/download/3/pdf-generaltechnicalinformation.pdf A good introduction to film capacitors

Acronyms used for film dielectrics:

BOPP: biaxially oriented polypropylene or just PP

PEN: polyethylene naphthalate, sometimes misnamed polyethylene

PET: polyethylene terephthalate, PETE, or polyester

PPS: polyphenylene sulfide

PS: polystyrene

Teflon® PTFE (DuPont) : polytetrafluoroethylene or TFE

Teflon® FEP (DuPont): fluorinated ethylene propylene

These are commonly used in industry so I use them here, when I remember.

Polycarbonate:

Trade names Cycolac and Makrofol. Polycarbonate has a fairly low temperature drift (lower than most films), dissipation factor, and dielectric absorption. It can be used in timing circuits, although C0G ceramics are a better choice for small sizes. It is suitable for some pulse applications, and for some precision analog applications, especially if you need its good temperature stability and relatively high temperature rating. Moisture absorption is high compared to other film dielectrics, a problem for some applications. Good heat resistance, to 125C, but not good enough to be found in surface-mount packages. Some manufacturers recommend it for automotive applications.

Unfortunately, polycarbonate may go the way of polystyrene. Polycarbonate has a higher moisture absorption that other common dielectrics which can cause some drift, it is prone to some defects, and has other problems. The last manufacturer of capacitor-grade film, Bayer AG, says they will cease production at the end of 2000, but may have a substitute material. A number of manufacturers are making recommendations for polycarbonate replacements (some of which should not be taken seriously). HYPERLINK "http://evox-rifa.com"Evox-Rifa for one, recommends polyphenylene sulfide, and this is probably the best choice for most applications. Polycarbonate has the edge in high-temperature leakage and is better at self-healing, but PPS is as good or better in most other parameters. PPS´s only weaknesses are a higher high-temperature temperature drift and higher DF at high temperature, >100C. Its K is about the same as PC, so PPS caps will be about the same size. Polypropylene may also be considered for applications where very low leakage is important, but high temperature is not a issue, although its temperature drift is not as good as PC or PPS. Polystyrene has had availability long after the film ceased production, but this may not happen with polycarbonate. Production is expected to cease no later than 2006. Unlike polystyrene, polycarbonate has only a few significant advantages over replacement dielectrics. PPS's main problems are that the capacitor-grade film is single sourced (Toray in Japan), expensive, and more difficult to process into capacitors than polycarbonate.

<Update>

Electronic Concepts Inc. ( http://www.ecicaps.com/ ) announced in 2005 that they are now making their own capacitor-grade polycarbonate film and are selling the finished capacitors. ECI specializes in upscale parts for aerospace, medical, and similar industries. As of 2014 polycarbonate capacitors are still on their website. More recently http://www.birkelbachfilm.de/ announced they would be selling polycarbonate film. We may not see small, cheap polycarbonate parts anytime soon, and a search of various distributors doesn't find a lot of parts.

Companies that list polycarbonate capacitors include:

Polyester:

Actually, polyester is a generic term for a class of similar polymers, the one used in polyester capacitors being polyethylene terephthalate. Dupont's trade name is Mylar. Some people call it PET, PETE, or PETP just to be confusing (and that doesn´t even include the various European trade names for it, like Diafoil, Hostaphan, and Lumirror). It doesn't really do anything particularly well but low cost, small size and the ability to do many things well enough makes it a good choice for many noncritical applications. High dissipation factor, especially at increasing frequency, means it is best used in DC or relatively low-frequency/low-current pulse and AC power applications. Poor temperature drift, dielectric absorption, and leakage relegate it to non-critical analog circuit applications. Typical applications would be where you want a capacitor larger than a C0G but better electrical properties than an X7R. Polyester capacitors can typically be found in values from 0.01 uF through at least 10 uF and beyond. Polyester has a high temperature drift but can be found layered with polypropylene to flatten the temperature curve (the two go in opposite directions). Polyester capacitors are available to 125C. Good heat resistance allows polyester capacitors to be made in surface-mount styles, but they are not common.

http://www.wima.com/en_index.php They have polyester SMD capacitors.

Polypropylene:

Polypropylene (PP) is a very popular capacitor film with about half the market. Other names are Torayfan,Treofan, and Trespaphan. The kind used in capacitors is called BOPP (or OPP, biaxially oriented polypropylene). There is another kind called HCPP. Polypropylene (PP) capacitors have a lot going for them. They are available in a wide range of sizes and voltages, and are used in a wide variety of circuits. PP has a very low dissipation factor over its entire temperature range and over a wide frequency range. Its self-healing properties, critical for reliable high voltage operation, may be the best. When an arc-through of the dielectric occurs, PP tends to leave less carbon at the site than polyester and other materials.

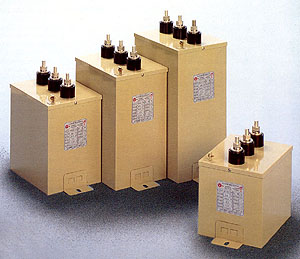

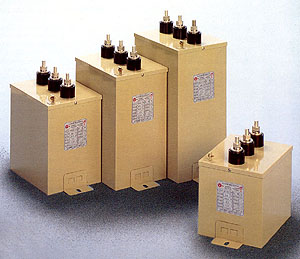

BOPP was a game-changer when it was introduced into the capacitor world. It became the material of choice for high-frequency, high-current applications like switching power supplies. Large film, film-oil, and paper-oil-film types are found in power-line applications like power-factor correction. These can have operating-voltage ratings >400 kV AC. Polypropylene motor-starter, motor-run, and SCR snubbers are replacing older electrolytic and paper-oil types which all have much higher dissipation factors. Sizes for these run into the 10s of uF and >500 VAC.

Polystyrene:

Polystyrene (PS), (the Europeans often call it "styroflex" or "styrol") has long been the material of choice for critical analog circuits. Low leakage, low dielectric absorption and a shallow, flat temperature curve makes these capacitors suitable for timing circuits, filters, integrators, and sample-and-hold circuits. Moisture absorption is very low. size, cost, availability, and temperature range limitations make polystyrene unsuitable for most other applications. Heat resistance is limited to about 85C, so forget surface mount. They can be damaged by soldering and by chlorinated board cleaning solvents. They can't be made in metallized film, only in film-foil.

Because of the poor heat resistance, polystyrene has largely been replaced by polypropylene and C0G ceramics, and the capacitor-grade film is no longer being made. There is several year´s supply still available, and they are still being sold, but be careful using them in new applications. Some manufacturers have noted that polystyrene caps are "not for new designs". One company, ITW Paktron, makes polypropylene capacitors with a guaranteed temperature drift similar to (if not quite as good as) polystyrene. PS's other electrical properties are mostly very similar to PP. However, polystyrene is sometimes used where its temperature slope complements other components, like ferrites used in some radios.

Whether polystyrene capacitors will really go away any time soon is not certain. I have been warned of polystyrene´s demise "in a few years" for several decades, and yet it is still available. There almost seems to be vast supplies of the film stashed away in manufacturers back rooms. Or maybe the film is being made in China. It may also be that declining usage will extend available stocks for many years to come. Many of polystyrene´s traditional applications are fading away as newer technologies take over. It is also claimed that with a lack of capacitor-grade film, capacitor makers have switched to the thicker commercial grade film which would result in larger, higher voltage capacitors. However, some 63 volt parts are still available (LCR Components from Farnell) so the truth might some combination of all these things.

Companies that advertise polystyrene capacitors (2009) include:

.

Distributors:

Polyethylene naphthalate:

Polyethylene naphthalate (PEN, Teonex), another form of polyester, is a relatively new material to the capacitor world. It has very good heat resistance, but is otherwise rather like polyester. It is available in larger sizes than C0G ceramic, lower temperature drift than polyester, and lower leakage than X7R. PEN capacitors are available to 150C. It is commonly found in SMD capacitors, including large values (>1 uF). PEN is new enough that new grades with improved properties are still emerging.

Acrylic:

Acrylic is a newcomer. The main attraction seems is size. C-D suggests it as an X7R replacement. Dissipation factor is high relative to other films, 0.5-1.5% through 20 kHz, temperature drift is only fair, and useful frequency range is limited to well under 1 MHz. Although the upper temperature limit is only 85C, they are only available in SMD. It is recommended for DC blocking for golden-ear audio applications but I would go with polypropylene. Their sizes, to at least 1 uf, make them suitable for bypass applications. Their high dielectric constant makes for a small size for things like pacemakers.

Just what is "acrylic"? Not being a chemist I don't really know. There are a number of patents on capacitors using "polyfunctional acrylate polymers", of which there are many variations. This may be what they mean.

Companies that advertise acrylic capacitors include:

The small through-hole styles are available in the usual range of sizes, roughly 100 pF-10 uF. Low leakage and low dielectric absorption make small polypropylene capacitors suitable for integrators and sample-and-hold circuits. Moisture absorption is negligible. Only its higher temperature drift makes it inferior to polystyrene. Polypropylene has limited heat resistance (to 105°C), and is not found in surface mount.

Polyphenylene sulfide:

Polyphenylene sulfide (PPS, Ryton, Torelina, Fortron) is another "newcomer", although it has long been used as an engineering plastic. It is found both SMD and in through-hole packages. It has many attractions, including low dissipation factor and very good heat resistance, a combination not found in other common capacitors. Dielectric absorption is fairly low. Probably the lowest for dielectric available in SMD. Moisture absorption is very low. One manufacturer says it has C0G-like electrical properties. This is a bit of an exaggeration but it is probably your best choice if you need a C0G-like capacitor >0.05 uF in SMD. PPS caps are commonly available to 150C. PPS is now being recommended as the main replacement for polycarbonate capacitors which may be going out of production. PPS's only serious drawback compared to polycarbonate is an increasingly high dissipation factor as the temperature goes above 100C. PPS has about the lowest temperature drift of film capacitors that still have good availability.

Teflon:

Teflon TFE is DuPont´s trade name for polytetrafluoroethylene or PTFE. Teflon is actually a blanket trademark for a variety of DuPont fluorocarbon polymers, 10-20 or so. About half have any commercial usage. PTFE is also sold under a number of other trademarks such as Fluoroplast-4 and Fluon PTFE. PTFE has very low leakage, very low dielectric absorption (probably the lowest in both cases), very low dissipation factor, a wide temperature range (to 200C for some), low temperature drift, negligible moisture absorption, and very good stability. It is about the best film capacitor for critical analog applications. Expensive, however, which is why you don't see them every day and few companies still make them. The film has exceptionally poor mechanical properties and inconsistent thickness, and manufacturers find it difficult to work with. It is hard to metallize and difficult to wind in large parts. Available from 0.001 to at least 2 uF. Have not seen them in SMD. Well, almost. CDE now makes a few Teflon SMD parts in very low values.

Which Teflon? Both PTFE and FEP are used. Manufacturers rarely say which one they are using but it's (almost) always PTFE. FEP has a low dissipation constant and good heat resistance like PTFE, but better mechanical properties I think. Both films have very poor availability and it's not certain that any given manufacturer will be able to deliver parts at this time. A Chinese company, Mianyang Prochema Commercial Co.,Ltd., says they make PFA capacitor film. I have never seen capacitors made from PFA however.

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19920010798.pdf

Companies that advertise Teflon capacitors include:

High Temperature Film Materials:

There is a growing demand for higher temperature capacitors. This has been lead in large part by the military and aerospace, but also by automotive and down-hole oil and gas industries. Most common films are usable to no more than 125C.

Teflon PTFE is traditional. It's usable to at least 200C and is good stuff in general. Expensive and it's supply is uncertain.

Aerovox UltraTherm is a modified polypropylene material usable to at least 140C. Patent pending.

Dupont Teijin Films has a material called Teonex HV usable to 150C. No information on just what it is. Possibly a modified PEN.

Electronics Concepts has an material called Thermakon usable to 150C.

Dearborn has a material called fluorene polyester usable to 250C. Developed with the help of the Air Force.

http://www.newark.com/ LCR Components has many part numbers, but not cheap

http://www.eci-capacitors.com/ I believe these guys make their own film

http://www.kitsandparts.com/caps_poly.php XICON polystyrene capacitors, whoever they are.

http://www.justradios.com/polystyrene.html Very good selection, plus various other parts, including kits. I have to wonder who makes them.

http://electrocube.com/ Recently, Electrocube started advertising PTFE parts, both foil and metallized.

http://www.scr.fr/en/products/power Teflon FEP capacitors, probably the only ones to make them. We are from France.

http://www.eci-capacitors.com/ Electronic Concepts, series MT1 Teflon capacitors which are hermetic.

http://www.semco-usa.com SEMCO is really a mica specialist, but apparently makes some Teflons in small values

https://www.solen.ca/pub/index.php?s1=1&a=2 Small Teflon FEP caps at high prices. Solen sells audio parts, speakers etc. Solen says they are made in France.

http://www.ebay.com Ebay always has lots of Russian Teflon capacitors. Don't know anything about them.