Whiskers are very fine filaments found growing from metal surfaces, most often plated. Whiskers were found in electronic

equipment at least as early as 1946. They are capable of causing short circuits and other problems. Whiskers don't just cause

failures in their own equipment, if disturbed they can float through the air and damage nearby equipment. Whiskers are mostly

associated with pure tin plating, but have been seen in silver, zinc, cadmium and even gold. Whiskering seems to be caused by

mechanical stresses caused by the plating process, but is also found in hot dipped zinc. This is interesting because computer

rooms tend to have a lot of zinc- and cadmium-plated hardware. The whiskers can dislodge and float into the computer

equipment. Whiskers are very fine, typically from <0.5 um to 10 um in diameter. Lengths can run from <1 mm to 10 mm (over

a third an inch). Shapes vary; some are bent, some are straight and some are other shapes.

Why does it happen?

Whiskering is not well understood. There is no General Theory of Whiskertivity. For example, it's not possible to reliably

predict when whiskering might start. It could take days to decades.

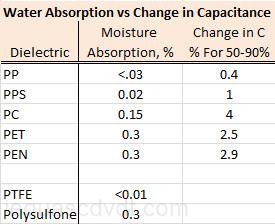

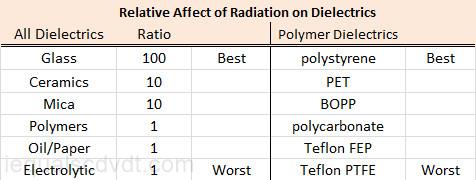

There are, however, some clear risk factors. Higher humidity seems worse than low humidity. Atmospheric contamination can

be important, silver whiskers are associated with sulfur compounds and the formation of silver sulfide. Contamination of plating

baths may be important in the case of gold. Contamination may play a role in many whiskers. Heat cycling with various levels

of humidity encourages whiskering and this is commonly used to test metals and plating. The fundamental cause is believed to

be "compressive stress" in the plating.

Where are whiskers found?

Everywhere...component leads and the end-terminations on SMD ceramic capacitors, lead frames, wirewrap pins, connectors

and sockets, relays and circuit breakers. That's just the beginning. Whiskers have been implicated in the failure of everything

from satellites to pacemakers.

What are the failure modes?

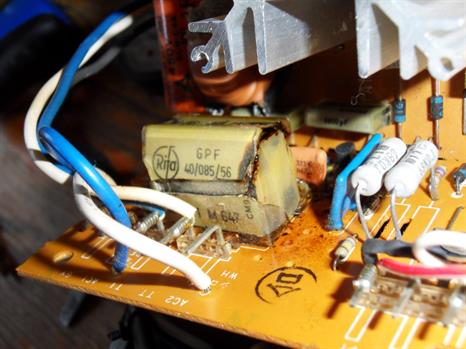

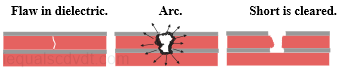

The common failure is a short circuit, either temporary or permanent. If there is enough current available to vaporize part of the

whisker, then the short will clear itself. If not, the short becomes permanent. In a vacuum, metal plasma can allow for arcs in

the range of hundreds of amperes if available. This can cause a catastrophic failure that can destroy a relay or circuit breaker.

At GHz frequencies, whiskers can act as antennas or affect waveguide performance. Whisker problems are potentially as bad

now as in past years, even though manufacturers are working to mitigate the problem. Voltages and currents in modern

equipment are going lower and lower making it less likely a short will be cleared. Spacing between parts is also dropping.

How can you see whiskers?

You don't need an electron microscope (but it helps). A stereo zoom microscope, 5X-100X, with adjustable illumination

(NOT a ring light) will usually work. You need to be able to move the light at any angle. Whiskers are very fine and difficult to

see and you need to get the light at the correct angle to the whisker.

How do you stop it?

In the 1940s this was easy, add a few percent of lead to the tin plating, as little as 3% (some people say <1% will do). Other

additives have not worked so well. Lead frames, for example, were commonly plated with up to 10% lead. For tin and zinc

this worked for many decades. Most people eventually understood not to use pure tin plating, even though the reason was not

always remembered. Thanks to RoHS this is usually no longer possible. The adoption of RoHS upset things and the whisker

problem has to be relearned.

There are a number of approaches to prevent whiskers:

If the cause is "compressive stress", then anything that can prevent or relieve this stress should prevent whiskering. Opinions still

vary...a lot. Matte finishes help or don't help, board coatings will or won't stop the problem, intermetallics (the plating metal

mixing with the underlying metals, usually copper) are or are not a factor. A nickel layer under the tin (to separate it from the

copper) will or won't stop whiskering. Silver has also been considered. Adding bismuth to tin might or might not be an answer.

Some companies already specify a small amount of added bismuth. Some people have proposed a reduced amount of lead in a

lead/tin plating. This probably won’t happen.

Stop using pure tin, zinc and cadmium. Satellite builders have moved from pure tin plating to nickel where possible. NASA

and the military still specify tin/lead plating and solder.

On circuit boards, use a reasonably hard board coating, such as a urethane or acrylic, of at least 2-3 mils. Soft coatings

(silicone) are known not to work well. Parylene is sturdy but goes on very thin and tests are contradictory. Some Parylenes

may work better than others. An advantage of Parylene is that it is very uniform, something not true of other coatings. NASA,

and probably others, has had problems with contractors delivering pure tin plating when tin/lead was specified. Perhaps all

assemblies should be checked with X-ray fluorescence equipment. This is sometimes done by the Europeans to test for lead

solder.

Many people have changed from bright tin to a matte tin finish over nickel. This approach may work but it has not convinced

everyone. They also relieve mechanical stresses with heat soaking for several hours at about 150C. This is now commonly

done with lead frames and SMD components. Probably both are required. There is evidence that a soldering temperature that

reaches the melting point of tin (232C) is very beneficial for some parts. There is also evidence that a thicker plating is better

than a thin one, to 10 um.

So, best practices seem to boil down to:

Matte tin over nickel. Matte tin has larger grains with lower internal stress.

Heat soak for several hours at 150C after platting.

Plating thickness of about 10 um.

Addition of about 2-3% bismuth to the tin. Much more than 5%, would affect soldering.

More information can be found below. The Panashchenko paper is an especially good introduction to whiskers with many

good pictures: