Sprague Bumblebee and Black Beauty capacitors:

There was a time when some capacitors were marked with NEMA colors just like resisters were. Bumblebee capacitors, a slang name never actually used by Sprague, gained fame because of their use in Gibson electric guitars in the 1950s (1956-1960?). They still have legendary status among some guitar players who will pay waaay too much for them, like around $100 a pair sometimes. They are considered to have awesome tone. Right.

The first Bumblebees were paper-in-oil (PIO), but after a few years they may have changed them to polyester or paper/polyester. Bumblebee fans seem to think that all 'bees were PIO. The oil was probably a special hydrocarbon oil and not a vegetable oil (as was often used in the past) or a PCB. Sprague used PCBs, but that came later I think. The bodies were Bakelite. Bumblebees were eventually replaced by Black Beautys with their parameters printed on the body.

The guitar people like the PIO version, but the paper/oil capacitors do not have the best long term stability. Besides using new-old-stock and "pulls", they also use rebuilt old capacitors (?), new reproduction PIO capacitors, and even vintage Vitamin Qs (96P, 196P and others) and Hyrels, hermetic versions very similar to the Black Beauty capacitors. Vitamin Q was actually the name of the mineral oil used. Hermetic PIO capacitors are claimed to be much more stable than plastic cased ones. There are also Russian PIO capacitors that some people like (K40Y-9, hermetic) that can be found on Ebay and a number of web stores. Bumblebees and Black Beautys were the same but sold to different markets, Bumblebees to OEMs and Black Beautys for sale for repairs and hobbyists. But which ones? Sprague made a confusing variety of Black Beautys from about 1950-1975, although Bumblebees seem to have been sold only during the late 1950s. You can probably match them up simply by value and voltage ratings.

The outer foil nipple is a tube and there is a legend that this is the "oil filler hole". Further, only PIO capacitors have them and Mylar capacitors do not. This is almost certainly not the case, although I don't have actual proof.

Over the years, Black Beauty capacitors variously used paper-in-oil (mineral oil), some with paper with a hard polymer (maybe a polyester resin), called HCX, that replaced the oil. Some used paper/oil with polyester (Mylar). In some series, the lower voltage parts did not use oil, but the higher did. There seems to have been some paper/wax parts very early on. Some used aluminum foil and some used metallized paper. Metallized paper can self-heal just like polymer dielectrics.

The numbers are read from left to right with the extra wide space being on the right (you can't always go by the outer foil nipple). So, the capacitor below is 22000 pF, 10%, 1500 volts DC. Note that the tolerance and voltage codes may not be exactly the same as used by other companies or other capacitor types. Sprague once made a cardboard decoder that sold for $.15.

http://issuu.com/williamcalvert/docs/black_beauty___bumblebee_capacitors

http://www.mylespaul.com/forums/vendor-classifieds/168654-mylar-50s-bumble-bee-capacitors-not-paper-oil.html

https://historicmakeovers.com/product/luxe-bumblebee-capacitors/

http://www.sovtube.com/ Russian electronics, including PIO capacitors.

http://www.radioremembered.org/capcode.htm

Obsolete Mica and Paper Codes:

Molded micas (sometimes called "stamp" micas) came in cases with molded-in "pockets" for colored paint dots that identified some combination of value, tolerance, voltage rating, vibration rating, temperature rating, and temperature drift. Paper capacitors used the same package. Sometimes the part values were printed on body, ignoring the paint pockets.

Over the years, people have used a bewildering number of ways of marking capacitors. Early on, capacitors were expensive and the parameters were printed on the case, sometimes partly by hand. Some of the earliest even had some parameters molded on the case. With the commercialization of small, cheap capacitors, some people switched to use color codes, at least on the cheapest capacitors. The first use of color codes seems to have started in the late 1930s and ended in the mid 1970s. Probably when it became possible to print on the capacitors less expensively.

Some of the organizations that published marking standards:

RMA: Radio Manufacturers Association, later known as RETMA, Radio Electronics Television Manufacturers Association.

EIA: Electronic Industries Alliance. The descendant of RETMA.

JAN: Joint Army-Navy Nomenclature system, later known as JETDS.

AWS: American War Standard. The same as JAN?

This is derived from a number of books and internet sources:

Allied Electronic Data Handbook, Eugene Carrington and Nelson M. Cooke. This is the best single source for vintage capacitor markings information that I have found. I have the 1962 edition but later editions have more information.

http://www.vacuumtubeera.net/Allied-EDH.pdf

http://www.electronics-tutorials.ws/capacitor/cap_5.html

http://www.americanradiohistory.com/Handbooks_Miscellaneous.htm A monster site covering the history of radio in particular and electronics in general. If you have any interest in the history of radio, this site is a must.

http://ethw.org/Archives:Dubilier_Condenser_Materials Lots of historical material.

Tropical fish capacitors:

Tropical fish capacitors, once sold by Philips and Mullard (a division of Philips by that time), were series C280, that used metallized polyester for their dielectric. The coating was lacquer. I have been told that all of these parts had five bands and this seems to be the case. Some appear to have four bands, perhaps because of adjacent bands of the same color, and some appear to have six bands because of incomplete coverage. If you see six bands, ignore the one closest to the leads. The chart below is typical of those found on the internet. Some charts show 5% parts, and 100V and 600V parts. There is no good evidence that such capacitors ever existed however. All the Tolerance bands I have seen have been black and white. This can help decode the values when the colors are ambiguous. Not sure why Mullard made them with color bands when they were making capacitors with actual printing at the same time.

There may have been a later version of the color code that covered other dielectrics but I haven't found any real evidence they existed.

The capacitor below is 22000 pF, 10%, 250V DC.

Vitamin Q:

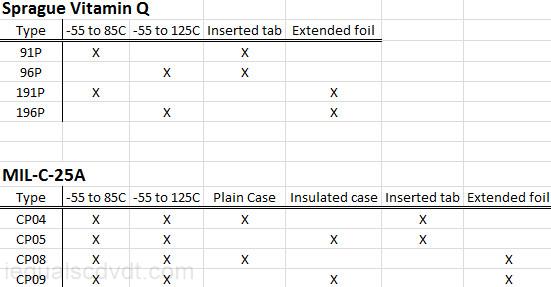

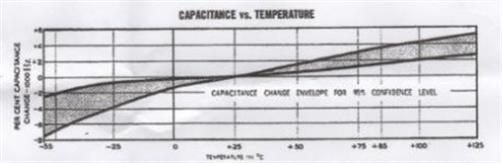

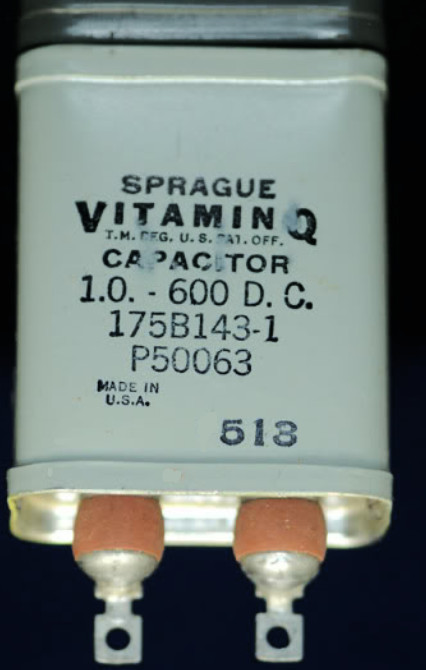

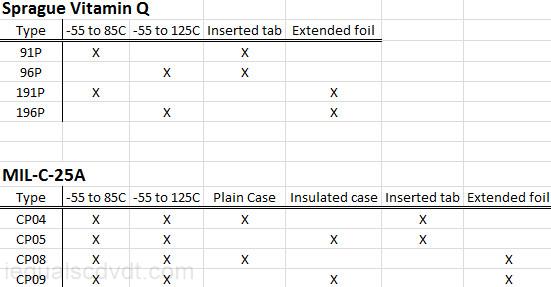

Sprague's Vitamin Q capacitors are hermetic (metal and glass), paper-in-oil parts. They were made in the 1960s, but NOS parts are still around today. They are more stable and reliable than non-hermetic paper capacitors. They are probably the favorite of golden-ear guitar people so I included them here. They come in two varieties, the MIl-C-25A equivalent (91P etc.) and the actual MIL-C-25A certified parts (CP04 etc.).

All of these parts have floating metal cases. Sprague also made similar capacitors with "grounded" cases (case tied to one lead) but I have never seen them. They are available in 10% and 20% tolerance.

Inserted tab: Each lead is crimped to a single point on its foil. Aluminum electrolytic capacitors are almost always made like this. However, these capacitors have high induction.

Extended foil: Each winding of the foil extends beyond the paper so the turns can be bonded together. This is how modern foil capacitors are made and the induction is much reduced. The size can be somewhat larger however.

Vitamin Q